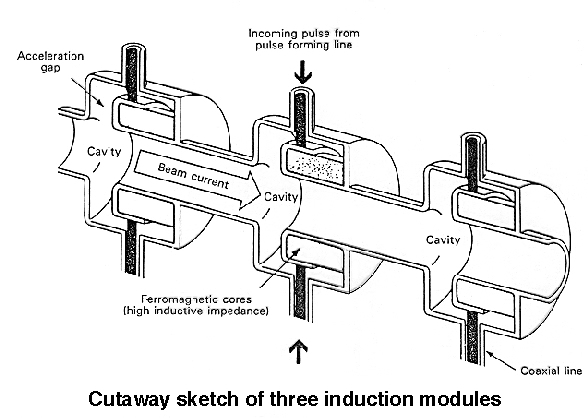

Induction-Module Development The induction accelerator is the type of driver

preferred by the US heavy-ion fusion program. In

this device, a pulsed electric field along the

accelerator axis is induced by increasing the magnetic

flux in a ferromagnetic core encircling the beam

pipe. In effect, each core is a one-turn

transformer, with the beam acting as the secondary

winding. The pulser used to drive the magnetic

flux, the induction core, and the gap across which the

electric field is produced are together called an

induction module or, equivalently, an

induction cell. The induction-module

research at LLNL and LBNL has three main

objectives: designing relatively conventional

modules for near-term experiments like HCX, developing

advanced pulsers and module geometries, and improving

the performance of insulators and cores. The induction accelerator is the type of driver

preferred by the US heavy-ion fusion program. In

this device, a pulsed electric field along the

accelerator axis is induced by increasing the magnetic

flux in a ferromagnetic core encircling the beam

pipe. In effect, each core is a one-turn

transformer, with the beam acting as the secondary

winding. The pulser used to drive the magnetic

flux, the induction core, and the gap across which the

electric field is produced are together called an

induction module or, equivalently, an

induction cell. The induction-module

research at LLNL and LBNL has three main

objectives: designing relatively conventional

modules for near-term experiments like HCX, developing

advanced pulsers and module geometries, and improving

the performance of insulators and cores.

Pulser design involves a trade-off between

flexibility and cost. For a fusion driver,

pulsers should ideally have high peak power, a 5-10 Hz

repetition rate, agile waveform control, and a

production cost less than $20/J. The least

expensive type of pulser consists of a passive

pulse-forming network (PFN) switched by a

sparkgap. This type of pulser, however, has poor

waveform control and a relatively short spark-gap

lifetime (~105 shots). Replacing the

spark gap with a thyratron increase the lifetime

(~106 - 107shots), but the cost

is substantially higher, and there is still little

wavefrorm flexibility. Solid-state pulser are

being studied, despite their even higher cost, because

they offer high reliability and long liftetime, as well

as allowing programmable waveforms. Under a

small-business research contract, Diversified Technologies

has investigated the use of low-inductance

Insulated-Gate Bipolar Transistors (IGBTs) for

switching, followed by magnetic pulse compression, and

has reported that such a hybrid system could meet

the performance requirements of a fusion

driver. Also, on a separate small-business

contract, First Point Scientific is developing a

solid-state pulser which will add corrections with a

voltage up to 20 kV to waveforms generated by more

traditional pulsers, allowing more accurate control of

the beam longitudinal profile. When complete,

this pulser will be tested on HCX.

Research into core materials and fabrication

techniques is being carried out in parallel with pulser

design. During the last five years, many

amorphous and nanocrystalline iron-based alloys have

been tested for their magnetic properties, uniformity,

and ease of fabrication. To minimize losses,

cores made from these materials must be built up in

thin (~2 x 10-5 m) layers, and each layer

must be insultated to prevent current flow across

them. Cores are typically fabricated by casting

or rolling the material into a thin ribbon, coating it

with insulation, and winding the ribbon onto a

spool. At present, amorphous materials are the

least expensive, but available insulating materials

that can survive the annealling process are either too

thick, degrade performance, or do not hold sufficient

voltage. Silicon steel is more expensive and has

high losses, but it is an alternative for longer pulse

durations due to its higher magnetic-flux swing.

Nanocrystalline steel is also more expensive than

amorphous materials and produces a lower voltage for a

given core size, but it is attractive for applications

where low core losses are important.

For comments or questions contact WMSharp@lbl.gov or DPGrote@lbl.gov. Work described here was supported by the Office of Fusion Energy at the US Department of Energy under contracts DE-AC03-76SF00098 and W-7405-ENG-48. This document was last revised June, 2002. |

The

work on advanced induction-module designs is aimed at

increasing the maximum voltage gradient across the

gap. The principal limitation on cell voltage is

electrical breakdown across the insulators, so

improved insulator materials are being investigated as

a way to increase the cell voltage. The

requirements for insulators are stringent, including a

surface-breakdown strength of 100 kV/cm, compatibility

with ultra-high vacuum (10-8 Torr), and high

mechanical strength. Nonetheless, recent tests of

Mycalex, layered insulators, and glass insulators show

promise, although these materials may exceed the $10/kV

production-cost target. Another approach to

increasing cell voltage is to design vacuum-insulated

induction modules with long radial insulators.

The principal questions about this approach are whether

a suffiently good vacuum can be achieved in an

accelerator to hold the required voltage and whether

heat generated by the cores can be dissipated.

The HIF-VNL is considering construction of an

induction-cell test stand both to examine major issue

of the vacuum-insulated cell concept and to test

various core configurations, insulator materials, and

cell geometries.

The

work on advanced induction-module designs is aimed at

increasing the maximum voltage gradient across the

gap. The principal limitation on cell voltage is

electrical breakdown across the insulators, so

improved insulator materials are being investigated as

a way to increase the cell voltage. The

requirements for insulators are stringent, including a

surface-breakdown strength of 100 kV/cm, compatibility

with ultra-high vacuum (10-8 Torr), and high

mechanical strength. Nonetheless, recent tests of

Mycalex, layered insulators, and glass insulators show

promise, although these materials may exceed the $10/kV

production-cost target. Another approach to

increasing cell voltage is to design vacuum-insulated

induction modules with long radial insulators.

The principal questions about this approach are whether

a suffiently good vacuum can be achieved in an

accelerator to hold the required voltage and whether

heat generated by the cores can be dissipated.

The HIF-VNL is considering construction of an

induction-cell test stand both to examine major issue

of the vacuum-insulated cell concept and to test

various core configurations, insulator materials, and

cell geometries.